Prior Lake Outlet Pipelining

Maintaining and improving the critical first leg of the Prior Lake Outlet Channel.

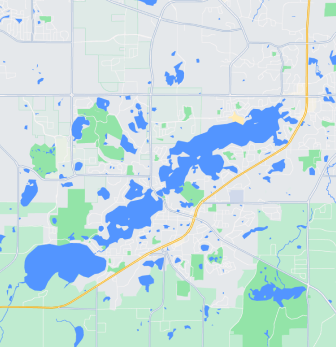

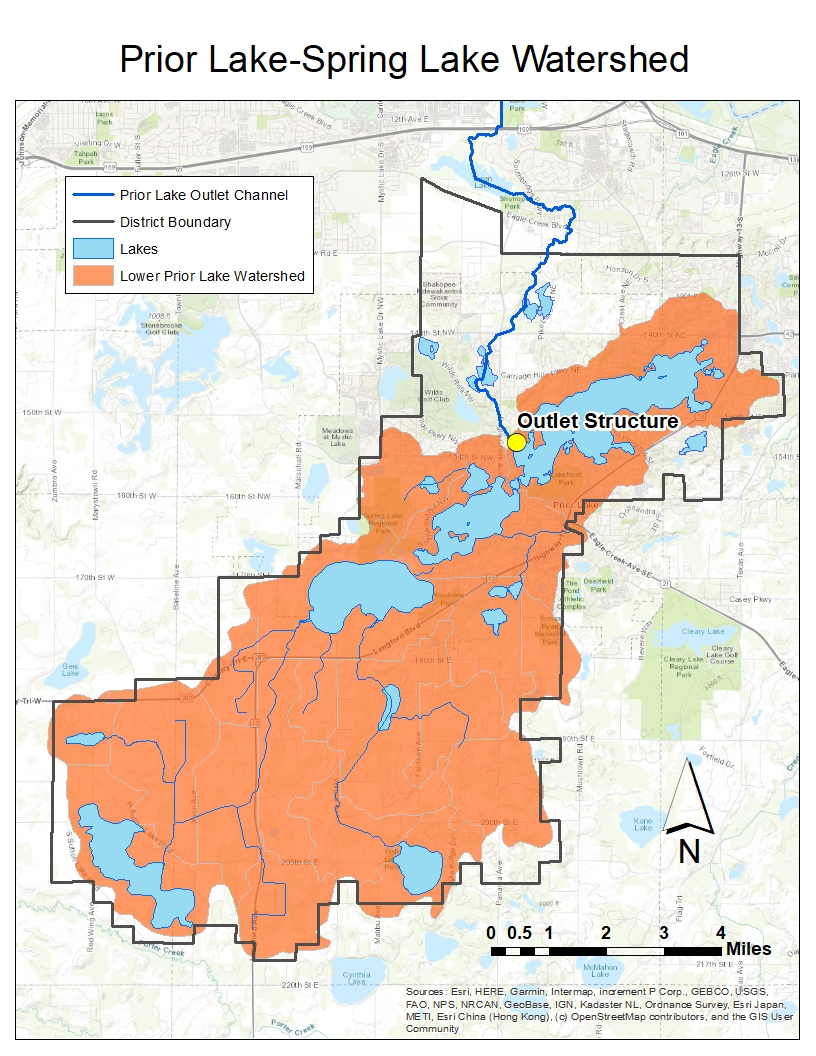

Project Location: Prior Lake Outlet Channel

Status Details:

The District and PLOC Cooperators were awarded funding from Minnesota Pollution Control Agency to support the pipelining in late 2024. The pipelining construction was completed in Spring 2025.

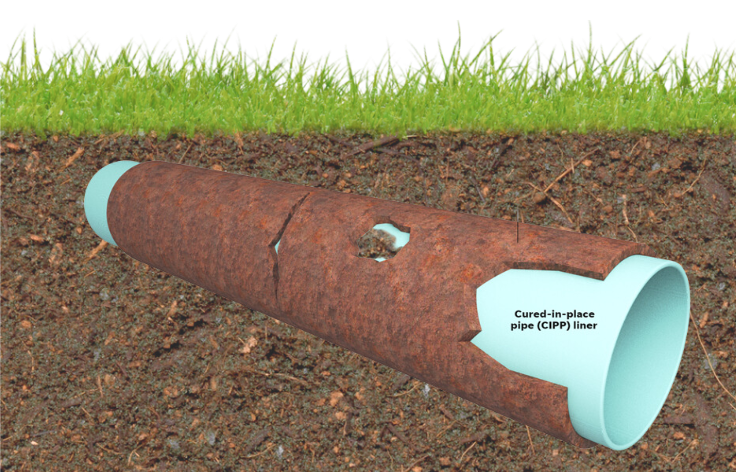

The Prior Lake Outlet Channel (PLOC) consists of a 0.4 mile section of pipe and then 7 mile open channel. The PLOC represents the only relief valve for the naturally landlocked Prior Lake watershed, making it essential to flood reduction. Built in 1983, the pipe has seen high use, and had reached the end of life. In order to maintain and improve the pipe's function, a liner was inserted through its existing manholes and cured to the surface of the existing pipe. This technology, called Cured-In-Place-Pipelining, requires no excavation. The result is a new, structurally sound, smooth pipe.

-

Pipelining In Action

Pipelining construction was completed in Spring 2025. The picture showcases how the pipelining is inserted down into the pipe through the existing manholes. The lining is inside out as it leaves the truck, and is pushed through itself into the pipe with pressurized air, much like you would flip a sock right-side out.

-

Drainage Area to Pipe

The Prior Lake Outlet Channel is the only outlet for Prior Lake. Over 30 sq. miles drain through the pipe, including portions of the Cities of Prior lake and Savage, Spring Lake and Sand Creek Townships, and the Shakopee Mdewakanton Sioux Community.

-

Pipelining Technology

Cured-In-Place-Pipelining extends the life of the pipe by 50 years, or equivalent to a new pipe. This technology is installed through the existing manholes, with no digging required. The smoother surface of the new lining will increase outflow by an estimated 15%.

-

2022 Pipe Inspection Image

Pipe inspections show cracks and leaks. Rough pipe walls slow down water evacuation during floods. The pipe sees more than 3 times the use of a typical stormwater pipe.

-

2014 Flood

The 2014 flood saw Prior Lake's water level rise 6 feet. Without a functional pipe, it would have risen 6 feet more. The 2014 floods resulted in millions of damage to public infrastructure, weeks-long road closures, and 58 homes inaccessible to emergency vehicles. The pipelining will reduce but not eliminate flooding.

-

Off-Cut from Cured Pipelining

After steam curing the pipelining, the liner becomes hard, equivalent to the surface and structure of a new pipe. The excess liner in the man hole and around bends are cut out and removed to leave a clean pipe-within-a-pipe.

-

Pipelining Material Before Curing

The image shows the pipelining before it is cured. The pipelining pre-curing is soft and flexible, with several layers similar to felt and a smooth exterior.

-

Pipe Condition After Lining

After the pipelining was complete, the entire pipe was jetted clean and televised to ensure proper installation. The smoother pipelining surface is estimated to reduce friction and increase flows by as much as 15%.

Benefits

- Maintains key infrastructure for critical flood reduction. The existence of the the PLOC has prevented Prior Lake from surpassing the ordinary high water level 11 times in the last 33 years.

- Increases flow out of the pipe by an estimated 15%. Allowing faster relief in times of need.

Timeline

- Summer 2023- Capital Investment funding application submitted to Minnesota legislature.

- October 2023- Presented at Capital Bonding tour for MN House of Representatives to request funding.

- December 2023- 95% design, and construction documents completed.

- January 2024- Presented at the Capital Bonding tour for MN Senate to request funding.

- March 2024- Submitted funding request to Legislative-Citizen Committee for MN Resources.

- April 2024- Submitted funding request to MN Pollution Control Agency.

- May 2024- Bonding bill was not passed in state legislature, and therefore funding was not included for the pipelining.

- August 2024- MN Pollution Control Agency awards maximum funding for 90% of eligible project costs.

- Spring 2025- Construction was completed in April and May, with site restoration completed in June.

Related Documents

Project Documents

Partners

- City of Prior Lake

- City of Shakopee

- Minnesota Pollution Control Agency

- Shakopee Mdewakanton Sioux Community